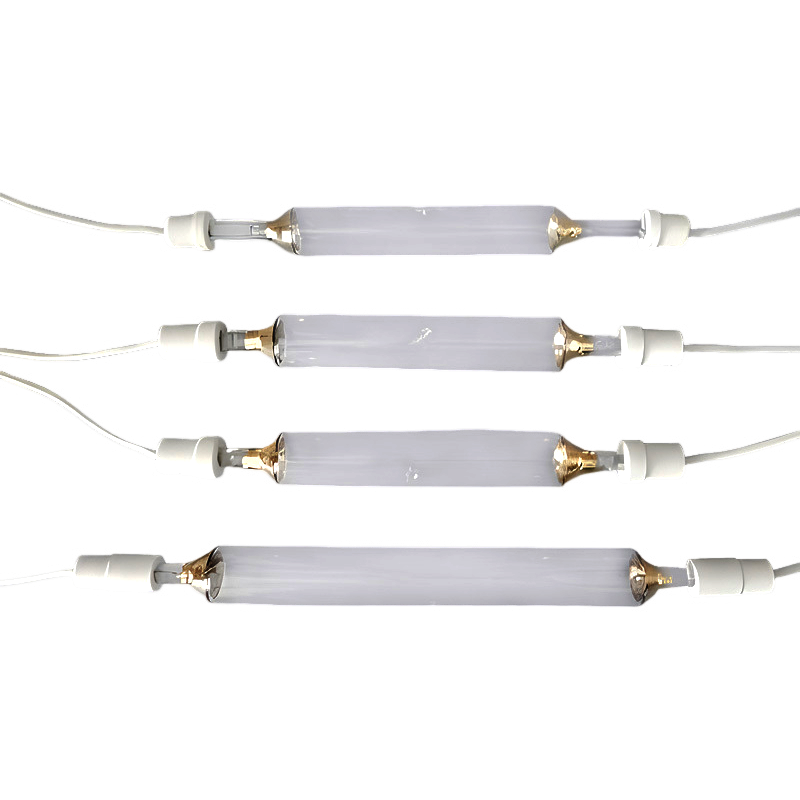

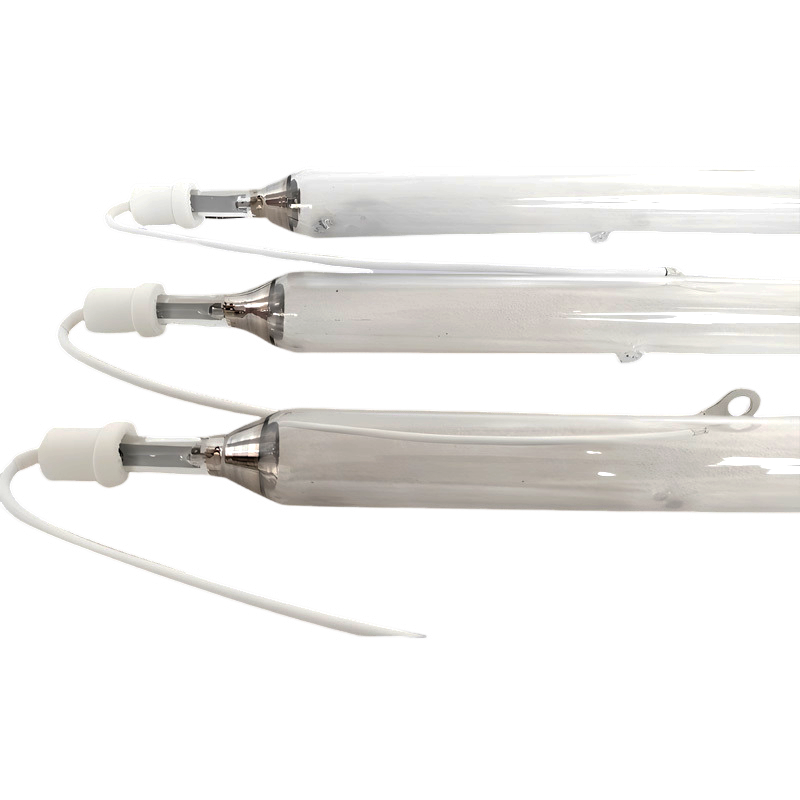

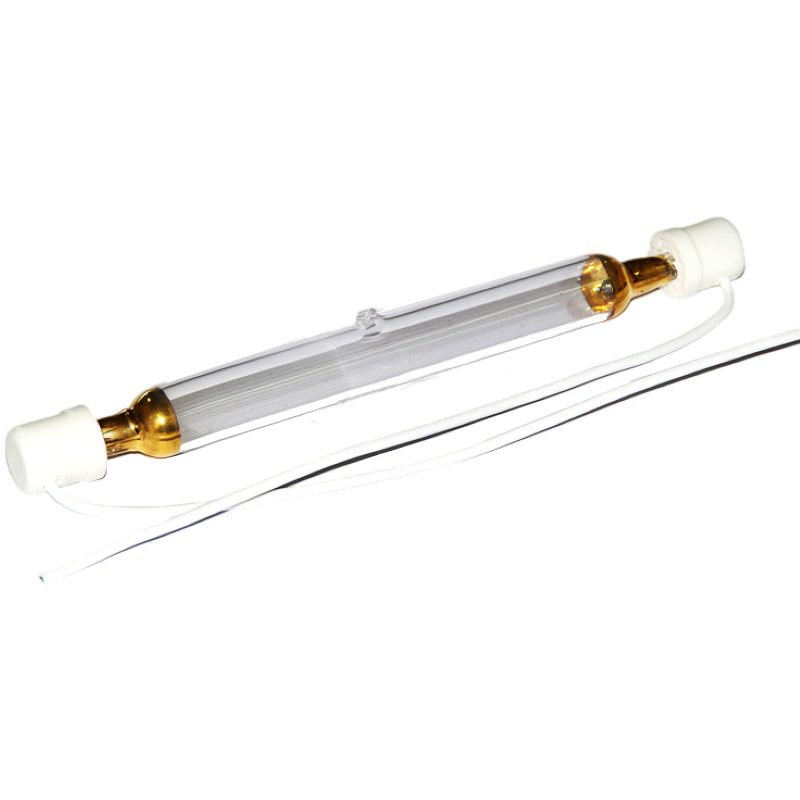

UV Curing Lamps for Printing

Scope of application

UV lamp for drying, areas of application

- UV printing: offset printing, letterpress printing, flexo printing, inkjet printing, adhesive, hot melt, permanently bonded printing;

- UV printing: for CDs; for electronic components; such as printed circuit boards and resistors;

- UV disinfection: sterilization and disinfection of food packaging materials, air, packaging films and taps;

- UV disinfection: sterilization and disinfection of food packaging materials, air, packaging films and taps;

|

serial number |

EYE model |

power |

length (mm) |

|

1 |

H01-L212 |

1KW |

221Y |

|

2 |

H015-L212 |

1.5KW |

275Y |

|

3 |

M015-L212 |

BG1.5KW |

275Y |

|

4 |

H015-L312 |

1.5KW |

220 Y |

|

5 |

M015-L31 |

BG1.5KW |

220 Y |

|

6 |

M015-L312C |

BG1.5KW |

220 Y |

|

7 |

H032-L21 |

3.2KW |

550Y |

|

8 |

M04-L31 |

BG4KW |

430Y |

|

9 |

M04-L31 |

BG4KW |

430Y |

|

10 |

H045-L31 |

4.5KW |

475Y |

|

11 |

H05-L21 |

5KW |

700Y |

|

12 |

M06-L31 |

BG6KW |

600Y |

|

13 |

H06-L22 |

6KW |

850Y |

|

14 |

H06-L31 |

6KW |

600Y |

|

15 |

M06-L61 |

BG6KW |

380Y |

|

16 |

M075-L31 |

BG7.5KW |

700Y |

|

17 |

H075-L31 |

7.5KW |

700Y |

|

18 |

M075-L51 |

BG7.5KW |

530Y |

|

19 |

M08-L41W |

BG8KW |

630Y |

|

20 |

M09-L31 |

BG9KW |

850Y |

|

21 |

M12-L61 |

BG12KW |

630Y |

Customization is possible according to parameters provided by the customer.

Lamp parameters

|

Model

|

Power

(KW)

|

Voltage

(V)

|

Current strength

(A)

|

Overall length (mm)

|

Arc length (mm)

|

Tube Φ (mm)

|

Lamp base

|

Peak of the waves

|

|

XUV 005004 FC

|

0.4

|

90

|

5

|

115

|

50

|

17

|

FC

|

365nm

|

|

XUV 020010 BC

|

1

|

135

|

8

|

335

|

200

|

22

|

BC

|

365nm

|

|

XUV 025020 AC

|

2

|

300

|

7.5

|

400

|

250

|

22.5

|

AC

|

365nm

|

|

XUV 025030 AC

|

3

|

700

|

5

|

360

|

250

|

25

|

AC

|

365nm

|

|

XUV 025040 DC

|

4

|

320

|

14

|

330

|

250

|

25

|

DC

|

365nm

|

|

XUV 070056 BC

|

5.6

|

950

|

7.2

|

825

|

700

|

25

|

BC

|

365nm

|

|

XUV 050060 AC

|

6

|

850

|

7.8

|

640

|

500

|

22.5

|

AC

|

365nm

|

|

XUV 065070 HC

|

7

|

928

|

7.4

|

780

|

653

|

22.5

|

HC

|

365nm

|

|

XUV 100080 BC

|

8

|

850

|

9

|

1172

|

1028

|

22.5

|

BC

|

365nm

|

|

XUV 124096 AC

|

9.6

|

1500

|

8

|

1387

|

1247

|

25

|

AC

|

365nm

|

|

XUV 112100 AC

|

10

|

1500

|

7.2

|

1260

|

1120

|

23

|

AC

|

365nm

|

|

XUV 130120 AC

|

12

|

1800

|

7.5

|

1440

|

1300

|

25

|

AC

|

365nm

|

|

XUV 120144 AA

|

14

|

2300

|

6.3

|

1328

|

1200

|

26

|

AA

|

365nm

|

|

XUV 077150 AH

|

15

|

1250

|

12

|

870

|

770

|

25

|

AH

|

365nm

|

|

XUV 107160 AC

|

16

|

2000

|

8

|

1185

|

1070

|

28

|

AC

|

365nm

|

|

XUV 150180 BC

|

18

|

1730

|

10.6

|

1600

|

1500

|

25

|

BC

|

365nm

|

|

XUV 105199 DC

|

19.9

|

660

|

30

|

1145

|

1055

|

27

|

DC

|

365nm

|

|

XUV 143200 AC

|

22

|

2000

|

11

|

1430

|

1530

|

28

|

AC

|

365nm

|

UV drying lamp is used for fast and efficient drying of various materials such as paints, varnishes, adhesives, polymers and other liquids. They work on the basis of ultraviolet radiation, which causes the polymerization process and accelerates the drying process.

UV drying lamps come in a variety of types, depending on specific needs and requirements. Some of the most common types include:

1. Low Pressure Lamps: These lamps have low voltage and power and are used to dry thin layers of liquids such as paints and varnishes. They are relatively low cost and are widely used in industry.

2. Medium Pressure Lamps: These lamps have higher voltage and power than low pressure lamps and are used to dry thicker layers of liquids. They are more expensive, but are also more efficient in drying.

3. High Pressure Lamps: These lamps have very high voltage and power and are used to dry very thick layers of liquids. They are the most expensive, but also have the highest drying speeds.

UV drying lamps can be used in various industries such as printing, automotive, furniture, electronics and more. They can help speed up the drying process, reduce equipment downtime and increase productivity.

When using UV lamps for drying, certain safety precautions must be taken, such as wearing protective glasses and gloves, and ensuring ventilation of the work area to avoid exposure of the skin and eyes to ultraviolet radiation.

*The above data is for reference only. CONTACT US for detailed information and customized solutions.