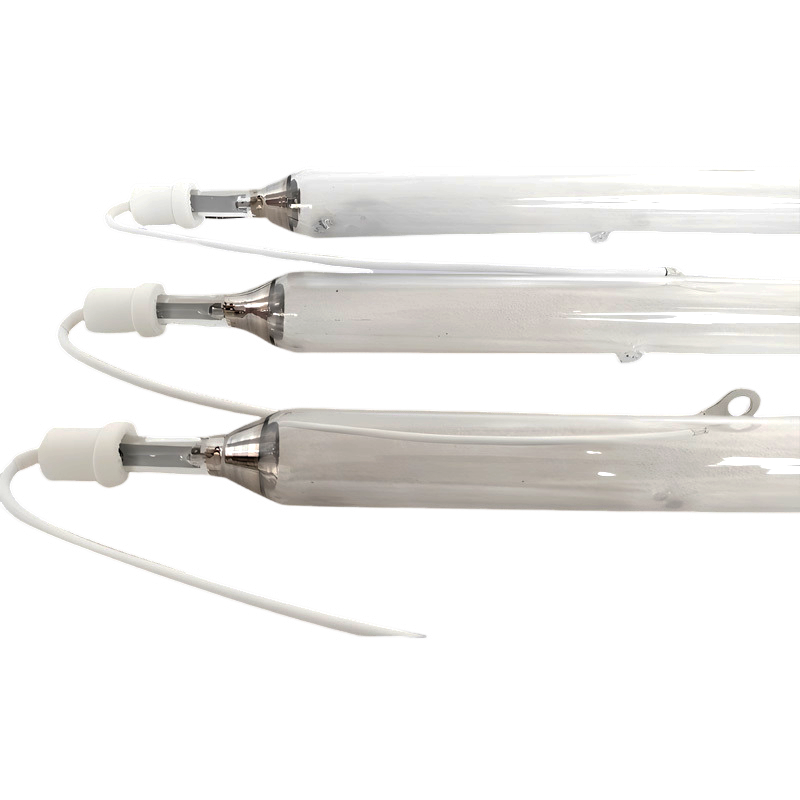

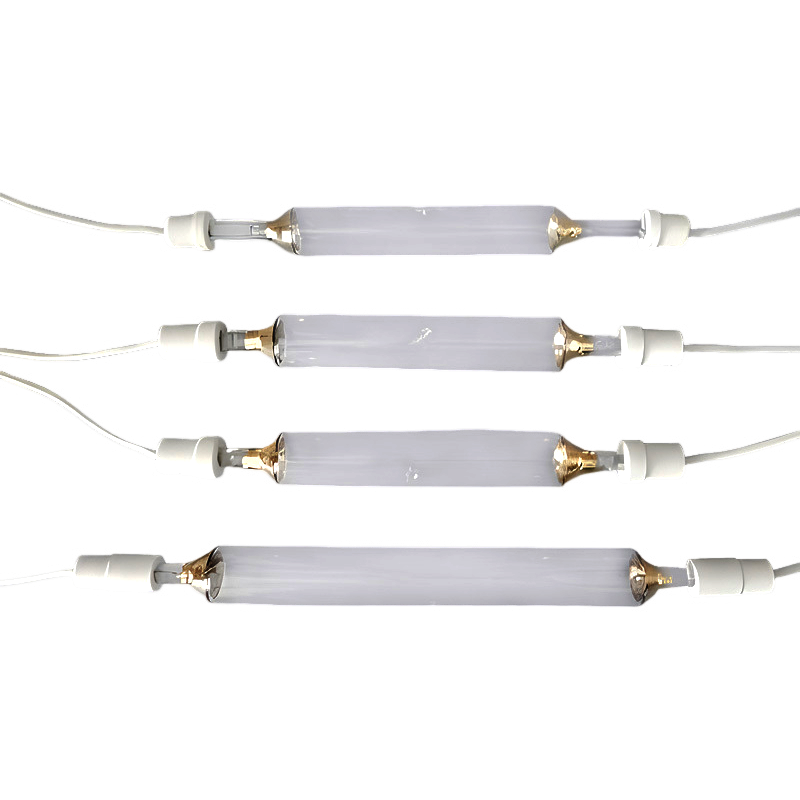

Ultraviolet Lamps

timeWith the rapid development of optoelectronic industry, the cleaning process becomes more and more important in optoelectronic products. Very often, ultraviolet lamps are used for this purpose. The influence of cleaning on the quality, precision and appearance of products is also becoming higher and higher.

At present, the cleaning method widely used abroad is low-pressure mercury lamp, which can avoid the pollution caused by the use of organic solvents and shorten the cleaning process.

Ultraviolet lamps, operating principle:

Photosensitive oxidation of organic compounds is used to remove organic substances attached to the surface of the material, and the surface of the material can achieve "atomic clean" after light cleaning. More specifically: the UV light source emits light waves of 185nm and 254nm, with high energy, when these photons impact on the surface of the object to be cleaned, most hydrocarbons have high absorption capacity for ultraviolet light of 185nm, absorbing the energy of ultraviolet light of 185nm They disintegrate into ions, free atoms, excited molecules, and neutrons.

Oxygen molecules in the air also produce ozone and atomic oxygen after absorbing ultraviolet radiation at 185 nm. Ozone also has a strong absorption of ultraviolet radiation at 254 nm, and ozone is broken down into atomic oxygen and oxygen.

Among them, atomic oxygen is extremely active, under its action, the decomposition of carbon and hydrocarbons on the surface of the object can be combined into volatile gases: carbon dioxide and water vapor come out from the surface, thus completely removing carbon and organic pollutants attached to the surface of the object.

Ultraviolet lamps, application:

- Liquid crystal displays;

- Semiconductor silicon wafers;

- Integrated circuits;

- High precision printed circuit boards;

- Optical instruments;

- Quartz crystals;

- Sealing technology;

- Metallic materials with oxide film and so on

Ultraviolet lamps, main application

- Optical glass

- Chrome plates

- Polished Quartz Crystal

- Silicon wafer and metal with oxide film for precision cleaning

It is used for cleaning:

- Organic dirt

- Human sebum

- Cosmetic oils

- Additives of resins and polyimides

- Paraffin

- Rosin

- Lubricating oil

This UV source also has the characteristics of UV modification (change in UV surface quality) during the LCD manufacturing process.

At present, in the production process of STN liquid crystal display, it is mainly used in film processing technology, which is very effective in improving the close contact between the film and the film, such as ITO film and photosensitive film layer, TOP coating and PI coating. In the R&D department, UV-modified plastic materials can also be used for nanotechnology research, the product under the action of ultraviolet light to chemical reactions, so that the surface properties of the product are changed.

During the production of STN-LCD, color filter and OLED display, some process equipment changes the surface properties quite impressively. In the production process of STN-LCD, color filter and OLED, some process equipment is quite similar, the difference is that the requirements for the production process are different.

With the improvement of the product line and color ratio, the LCD industry's requirements for the production process are constantly improving, and there is a demand for "workers to do their job well must first benefit their tool", so only the equipment performance is constantly improved to improve the quality and efficiency of production.

You can find out more information, order a lamp, and also get more detailed information by contacting our manager .

*The above data is for reference only. CONTACT US for detailed information and customized solutions.