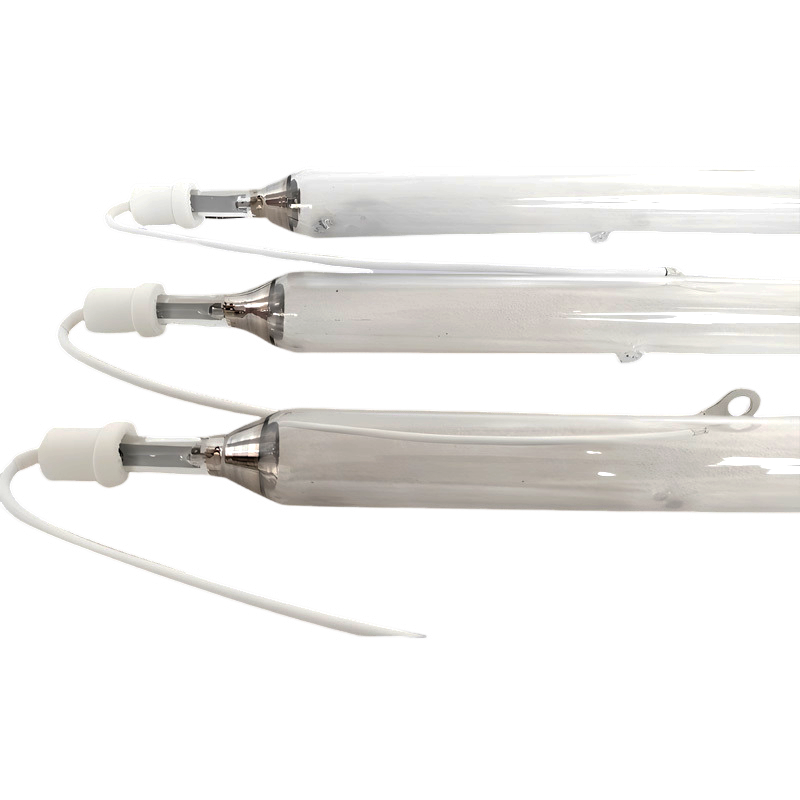

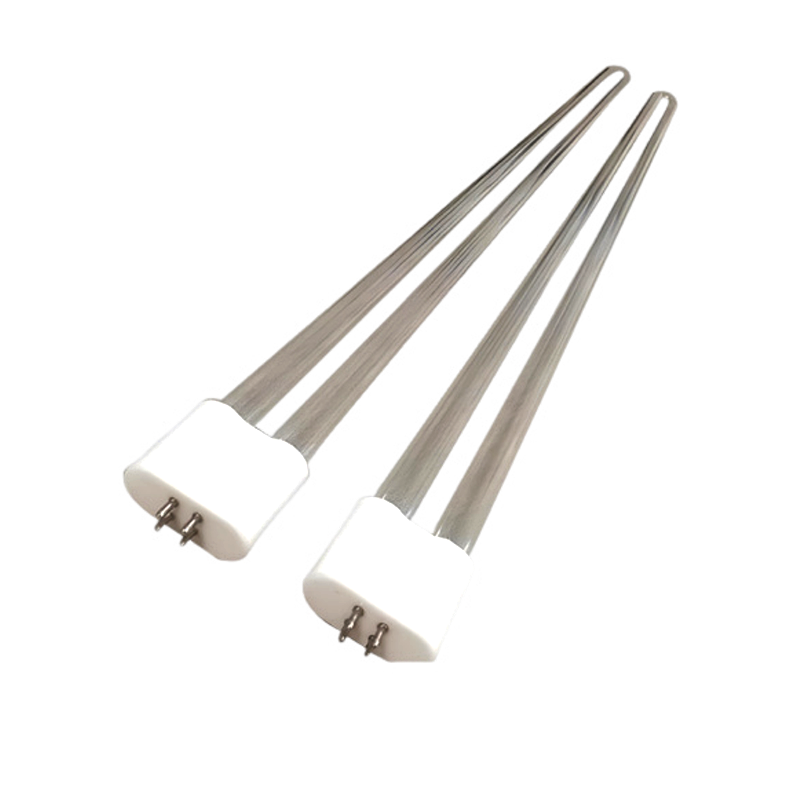

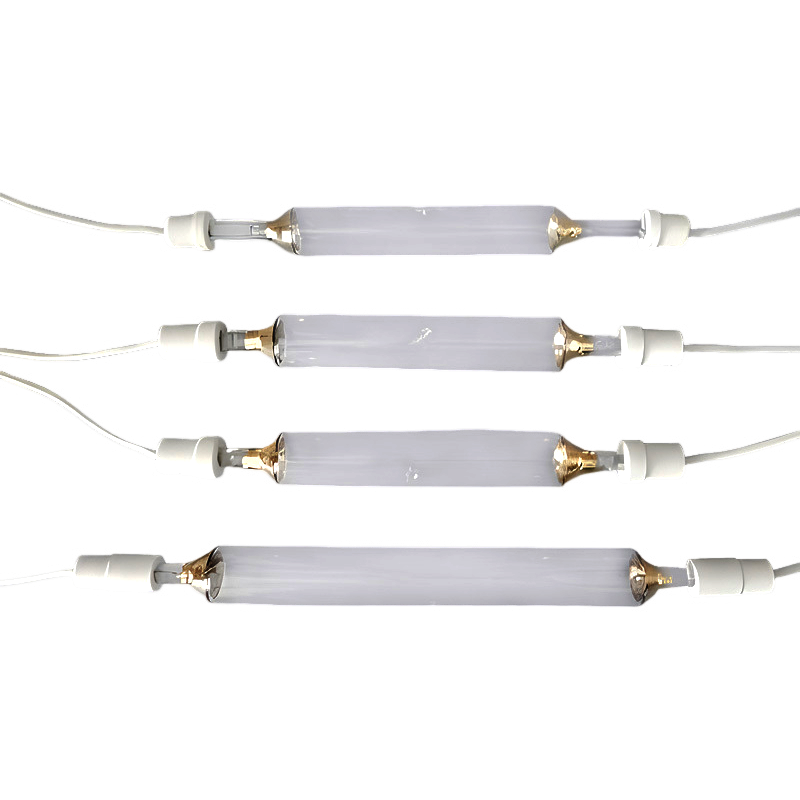

UV-Trocknungslampen/UV-Härtungslampe für den Siebdruck

What are UV drying lamps

Developed on the basis of the high-pressure mercury lamp, this type of lamp is made of a high-purity quartz tube filled with mercury, argon and gallium iodides, iron iodides and halides of some rare metals. There are too many empty spots in the spectrum around the 365 nm wavelength.

The use of elements whose emission spectrum is in this wavelength range provides high vapor pressure at a certain temperature, creates dense light spectra in this wavelength range, increases the efficiency of UV radiation in this wavelength range by 1–2 times, and then increases the efficiency of electrical energy and the curing rate during operation.

Gallium iodide can introduce 403nm and 417nm spectral lines into the spectrum of UV printing lamps, which is greatly applied in the processing of nitrogen compounds; Iron iodide is a halogen that can provide broad-spectrum UV radiation and increase the output power of the lamp in the 380nm spectrum.

UV printing lamps with the addition of iron iodide can provide good effects in the exposure system of photopolymers and sunlight photographic films.

The energy spectrum of UV lamps for printing can match the adsorption spectrum of some materials very well and can cause the curing reaction very quickly.

UV lamp imported model

|

brand |

AMBA model |

Notiz |

|

AM10001X |

M48/300 |

|

|

AM10000X |

H48/300 |

|

|

AM10267X |

H48/350 |

|

|

AM8671X |

M48/350 |

|

|

AM10746X |

H36/300 |

|

|

AM10747X |

M36/300 |

|

|

AM10061X |

H50/270 |

|

|

AM5528X |

H50/270 |

Side release |

|

AM10319X |

M50/270 |

|

|

AM10248X |

H70/270 |

|

|

AM10015X |

M12/500 |

|

|

AM6045X |

IST 1050 K3H |

|

|

AM5577X |

T1050 K2H |

|

|

AM4293X |

T770 K2H |

|

|

AM4911X |

T770 K3H |

UV lamps for drying, application

- cinema

- silkscreen printing

- printed circuit board manufacturing

- seal

- in industrial surface coatings

Want to order an ultraviolet lamp for drying? Check the availability of the device with our manager .

*Die oben genannten Daten dienen nur als Referenz. KONTAKTIEREN SIE UNS für detaillierte Informationen und maßgeschneiderte Lösungen.