UV Medium Pressure Lamps for Ballast Water Treatment in Ships

UV Medium Pressure Lamps discriptions:

Ultraviolet (UV) radiation, ranging from 750 THz to 30 PHz in frequency and with wavelengths from 400 nm to 10 nm in a vacuum, is a collective term for electromagnetic radiation that exists in sunlight and has a higher frequency than visible light. It can be categorized into the following types:

UVA: Wavelengths from 400 nm to 320 nm;

UVB: Wavelengths from 320 nm to 280 nm;

UVC: Wavelengths from 280 nm to 100 nm;

EUV: (Extreme Ultraviolet): Wavelengths from 100 nm to 10 nm.

In the context of electrical power systems, the following terms and their English translations are commonly used:

- (Low Voltage): Voltage levels with a nominal voltage of 1kV and below are defined as low voltage.

- (High Voltage): Voltage levels with a nominal voltage above 1kV and up to 330kV are defined as high voltage.

- (Medium Voltage): The term "medium voltage" is also commonly used. According to the standards of the Institute of Electrical and Electronics Engineers (IEEE), voltage levels between 2.4 kV and 69 kV are referred to as medium voltage. In China's (SG) normative documents, voltage levels from 1 kV to 20 kV are classified as medium voltage.

In the field of water treatment, ultraviolet (UV) disinfection, particularly in the C range (UVC), has always played a significant role. There are common low-pressure and medium-pressure ultraviolet options:

- (Low-Pressure Ultraviolet): Low-pressure ultraviolet can meet the water treatment requirements for general flow rates and is suitable for systems that require frequent on-and-off operations. It has a high UV conversion efficiency, up to 40%, and low costs, making it widely used in municipal water supply, surface water, industrial water, pool water, landscape water, recirculating cooling water, ship water, seawater desalination, and small-flow water disinfection.

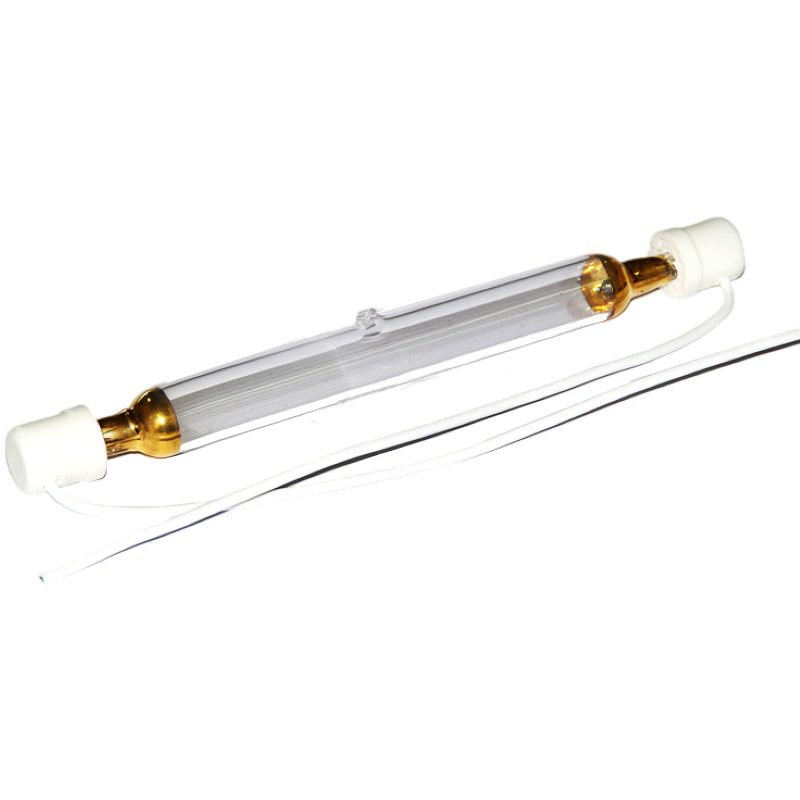

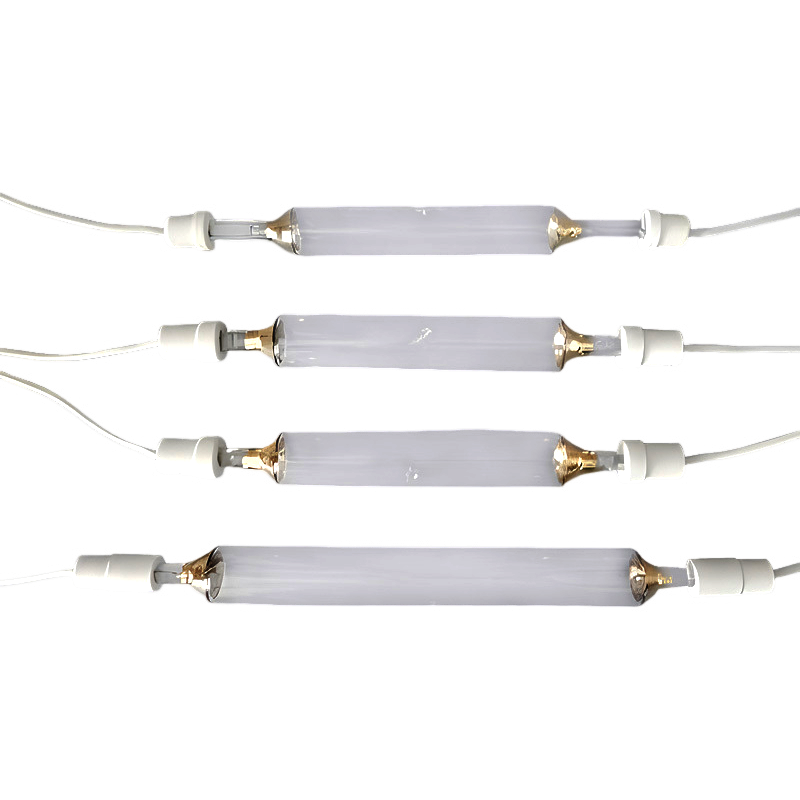

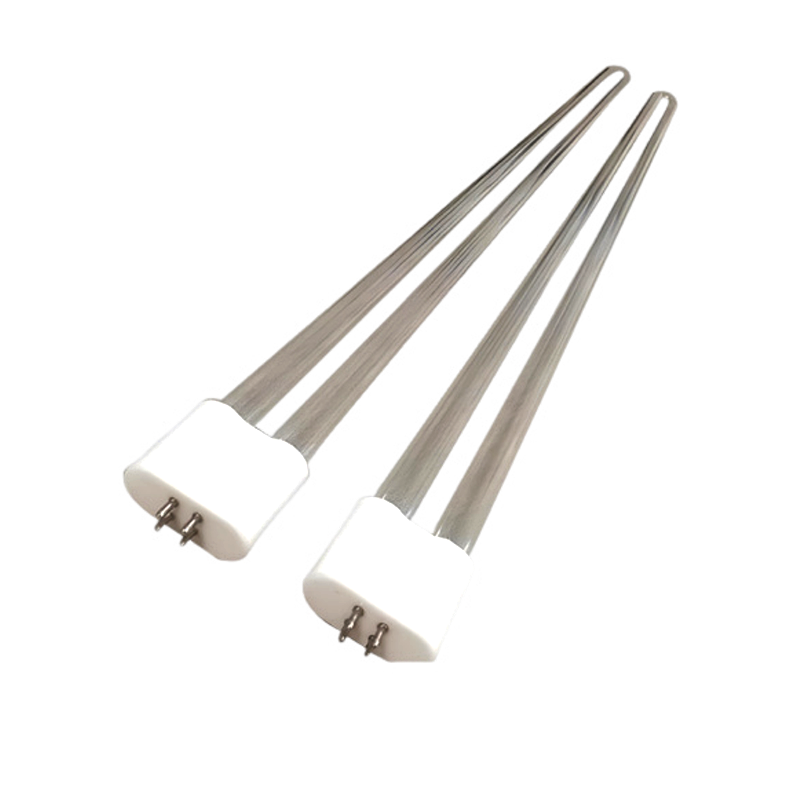

- (Medium-Pressure Ultraviolet): Medium-pressure ultraviolet lamps have an internal inert gas pressure equivalent to atmospheric pressure, ranging from 0.2Mpa to 0.4Mpa, which is 100 times that of low-pressure lamps. They can emit a broader range of wavelengths, between 200nm and 400nm, which is more effective in destroying microbial organisms or preventing their replication, achieving the purpose of disinfection.

Applications include water treatment, air purification, waste gas treatment, photo cleaning, grease purification, ink curing, and various industries such as fish meal factories, chemical plants, spray painting factories, electronics industry, oil refineries, waste-to-energy power plants, rubber factories, pharmaceutical factories, sewage treatment plants, paper mills, tanneries, paint factories, etc.

According to the provisions of the International Convention for the Control and Management of Ships' Ballast Water and Sediments, the so-called ballast water treatment refers to mechanical, physical, chemical, or biological methods taken to kill or render harmless aquatic organisms and pathogens in ballast water and sediments, or to prevent their ability to reproduce.

---Ultraviolet Radiation Method

Exposing ballast water to ultraviolet light can kill bacteria and other microorganisms in the water. The treatment process does not produce secondary pollution, and the equipment is easy to operate and manage with low operating costs. However, this method cannot kill all harmful aquatic organisms, and its effectiveness is greatly affected when the seawater is turbid or the lamp surface is contaminated by sediments. It can be used in conjunction with filtration for better results. This treatment method is more feasible for ships that carry a small amount of ballast water or do not need to discharge quickly, such as cruise ships, warships, and container ships.

Medium-pressure mercury lamps have high linear emission intensity in the UV-C region, with the main spectrum ranging from 310 to 1000nm. The spectral peak values are: 300nm, 303nm, 313nm, 334nm, 366nm, 405nm, 436nm, 546nm, and 578nm, with power ranging from 250w to over 20kw, and customizable lengths.

Advantages of medium-pressure mercury lamps:

Compact structure, space-saving

The structure of medium-pressure mercury lamps is smaller than that of low-pressure mercury lamps, allowing for the design of smaller reactors, especially suitable for high-flow water treatment.

Automatic light power adjustment

The output of ultraviolet light can be adjusted according to parameter changes (such as water volume), which has more automated adjustment capabilities than low-pressure mercury lamps.

Multi-band emission, good disinfection effect

Medium-pressure ultraviolet disinfection devices are multi-colored (i.e., emit at several bands), and a portion of the light (at least 40%-50%) is directly useful for disinfection.

Domestic production of medium-pressure mercury lamps, reducing costs

We have domesticated imported lamp tubes to reduce your usage costs without compromising product quality or effectiveness.

*The above data is for reference only. CONTACT US for detailed information and customized solutions.